ELECTROPOLISHING LARGE VESSELS

Electropolishing of chambers, manifolds and housings.

Customers rely on NEE for precise and consistent finish, from one part to 100,000.

Unrivaled expertise

NEE has the capacity to electropolish and passivate your large vessel fabrications up to 8’ long by 5’ in diameter. Our expertise includes:

- Thorough understanding electropolishing large vessels – From rigorous surface finishes to aesthetic requirements, NEE can meet your requirements.

- Expert surface prep – NEE specializes in the tooling, masking, and surface preparation often needed due to the wetted surfaces, ports and flanges of large vessels.

- Design and in house fabrication of custom cathodes – To ensure we meet your specifications, NEE designs and fabricates custom cathodes, a critical component of the large vessel electropolishing process.

Companies in the pharmaceutical, vacuum, marine, architectural and food service industries turn to NEE for their large vessel electropolishing needs. Our process fully complies with ASTM B912, “Standard Specification for Passivation of Stainless Steel Using Electropolishing.”

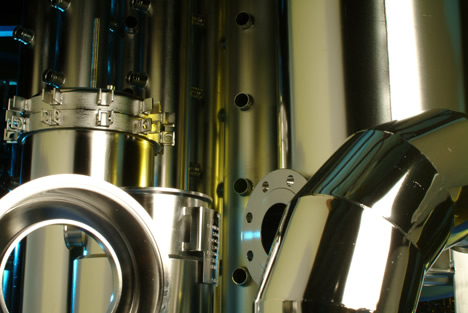

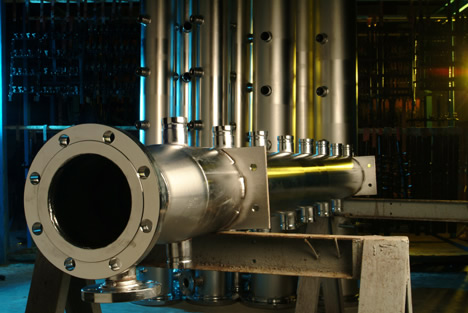

NEE specializes in stainless steel finishing of very large parts, such as this 10’+ manifold, part of a water purification system.

NEE’s capabilities include electropolishing large bulky items, such as the finishing of this stainless steel housing. Electropolishing helps reduce corrosion and gives parts a clean, uniform finish.

Custom cathodes and our large electropolishing tank ensure NEE meets your specifications for large parts, such as these stainless steel vessels.

"The secret to our success is two-fold. We do one thing and we do it well. The other is that we're uinited around one simple goal: to exceed your expectations."

Amy AlmeidaVice President, Finance & Administration

Exclusive Offer

Free sample part electropolishing

Send us your sample part and we’ll electropolish it and return it to you with a project quote and delivery schedule – no charge.